About ERP and MES

Some ERP implementers see MES as an extension of their ERP software. While it may seem like a logical extension of their business, there are some pitfalls that should be considered when designing your company’s software architecture.

Focus on Strenghts

ERP focuses on enterprise operations, which involve all office-related tasks. The MES layer links the office and operations. It must act as the flexible joint between the two. This can be compared to the constitution of the human body: rigid elements are connected by joints, enabling flexible movement. As we know, ERP systems are rather rigid and should be customised as little as possible. However, this is acceptable for business operations, as adapting to the software can be beneficial.

Conversely, the operational side should not be forced to adapt to rigid software, because your processes constitute your company's know-how and competitive advantage. This is why an MES must act as a flexible joint and absorb the layers. This requires an open, easy-to-configure structure, as well as an implementation partner that can deliver this. This is the opposite of the philosophy of ERP development firms today.

The MES solutions offered by ERP implementers are, in most cases, limited to screens for start- and stop instructions on work orders. In our view, an MES is a different kind of software that requires a different approach and knowledge. Office tasks are mostly translated into procedures, whereas operational topics are translated into processes. This clearly emphasises the distinction between the two.

Functional elements

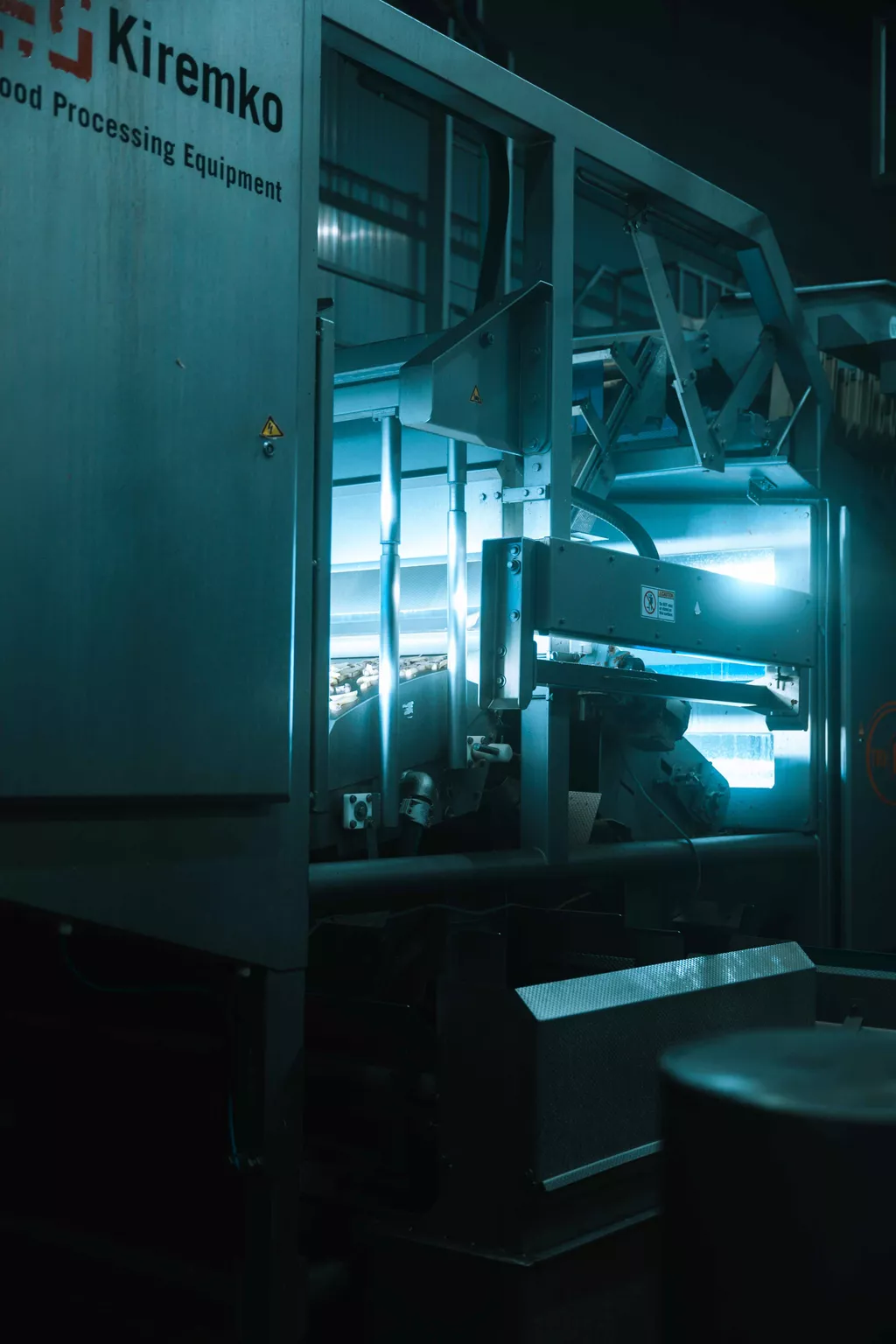

Machine integration

Controlling complex machines is not as simple as using easy-to-configure software. It requires hands-on knowledge and experience of two areas: machines and electronics, and software and coding. Similarly, you wouldn't ask your carpenter to connect the piping and cables, even if they were the best in their field. Production environments are also not static for decades on end. Constant changes, replacements and expansions mean that production is the most demanding area of your business, so responsive software and a responsive software partner are essential.

Quality

Digitising quality is essential. It will transform your organisation, increasing efficiency, effectiveness and reducing costs. This applies not only to production, but to all departments. Improving quality supports the customer, resulting in commercial success, as well as the company's core operations. Quality is an interaction between software and operator. It provides instructions to the operator and accepts input from machines. Track & trace provides underlying, automated administration.

Work instructions

The same benefits apply to digital work instructions. The hassle and frustration of distributing tasks on paper is a thing of the past. In their place comes structure, enabling the enhancement of information for operational activities and propelling the company forward once again. Ease of command and execution brings satisfaction at all levels.

Planning

Fine scheduling is the flexible and dynamic translation of ERP planning. It is not a replacement for ERP planning but rather fulfils the practical needs of operations instead of taking a theoretical approach. In practice, many unforeseen events influence this planning, which must be absorbed flexibly and intelligently for optimisation.

If the planning process is too complex for the ERP environment, advanced planning and scheduling (APS) can be embedded within a manufacturing execution system (MES) to connect planning with shop floor execution. Integrating advanced planning and scheduling into the MES provides organisations with real-time, constraint-based production schedules that reflect actual conditions, such as machine availability, material status, and labour capacity. This improves delivery reliability, shortens lead times, and optimises the use of resources. It enables faster decision-making and proactive handling of disruptions while keeping planning and execution aligned to improve efficiency, flexibility, and overall manufacturing performance. Operations require a multifunctional, user-independent application that caters for the needs of each user type and their different functional emphases. The aim is to provide insight and control where and when needed, in a way that is compatible with the surrounding software architecture.

Control

Monitoring operations through an MES provides real-time visibility into shop-floor activities and performance. By capturing and analysing production data, organisations can gain clear insights into efficiency, bottlenecks, and deviations. The MES is particularly suited to this because it focuses on large volumes of data. Sometimes, this data is collected at a high frequency. This data is directly relevant to operators and supervisors, while remaining accessible to office-based roles such as planners and managers. This enables faster responses, better operational control and more actionable insights, all without overloading the ERP system.

Software integration

The MES application layer communicates with both ERP and operations. The data conversation includes not only ERP, but also warehouse, logistics and other software platforms. Furthermore, it is not only in-house systems that link up, but also suppliers, customers and third parties. Software integration must be a core competency of your MES partner. Without this capability, you will repeatedly encounter dead ends, which is not only frustrating due to the waste of time, energy and money, but also due to the lack of progress and the feeling of falling behind.

Future thinking

We all depend on IT/OT and its extensive range of hardware and software. The benefits outweigh the dependency, so we allow it. But one thing is certain, based on the years of experience we have all gained by now: nothing evolves faster than the technology world. What is cutting-edge today will soon become outdated. This constant evolution brings upgrades and updates, as well as replacements. Currently, we are seeing many companies transition to the next generation of ERP systems, and we are aware that these are very intensive implementation processes. Replacing both ERP and operational software simultaneously could be fatal for the company. This is why we believe it is essential to decouple the MES layer from the ERP in terms of both software and provider.