Allgro

From the field to your plate in no time.

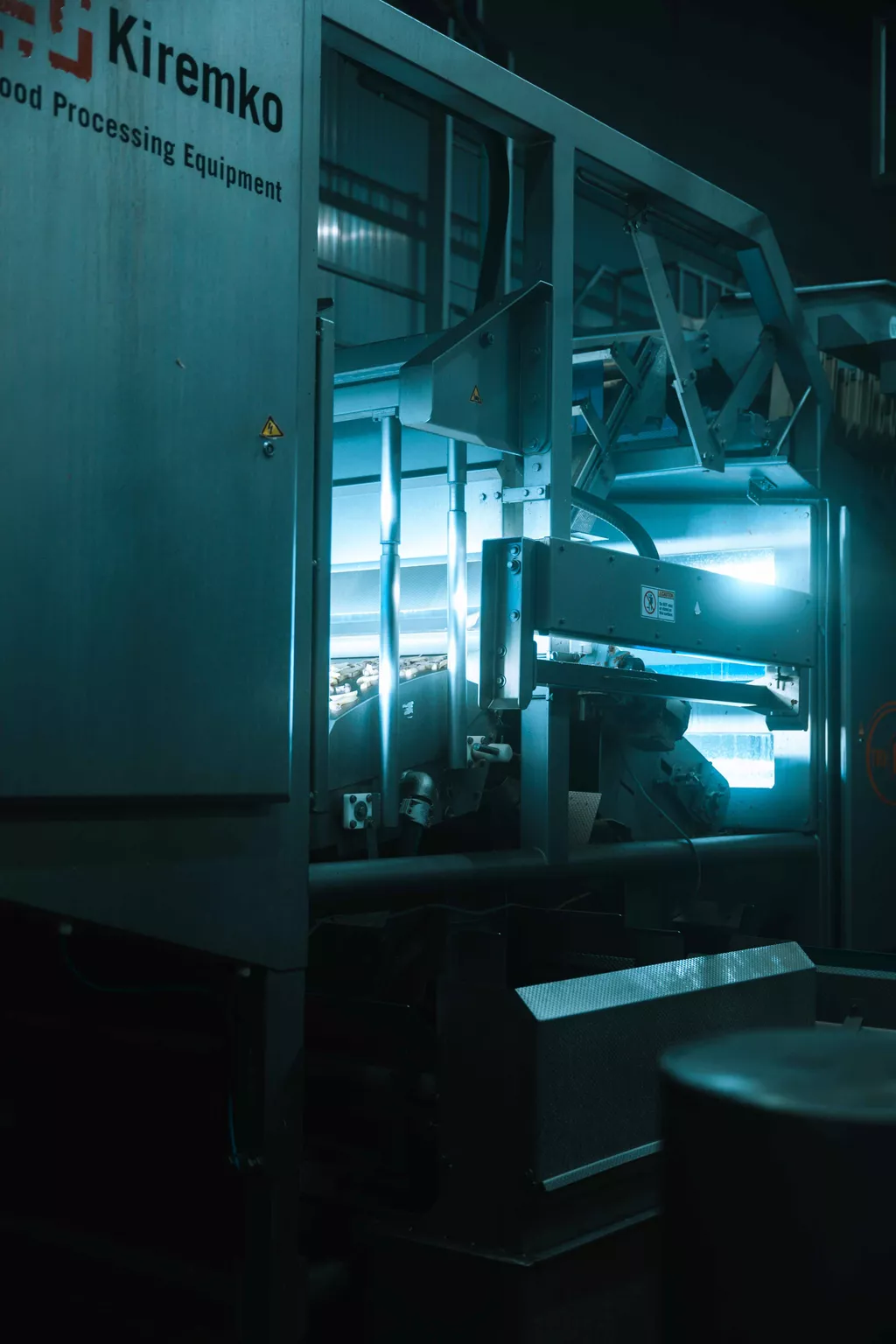

Orchestration of crispy cut vegetables

It might not be the first thing you think of, but innovation is at the heart of Allgro. It is what drives excellence when you are a top supplier of freshly cut vegetables and fruit. Again and again, the challenge is to deliver top quality at speed, portion-packaged, tailored to the customer’s needs. So yes, it is a story about efficiency and quality where the orchestration of people, machinery and software is highly important. The only way to make this process run smoothly is by implementing production software. It directs both people and machines but also safeguards the level of quality that is so crucial to the customer.

Complexity too hard to fit

This belief was already present when we first spoke with Allgro. The issue, however, was dissatisfaction with their previous software supplier. The solution could not meet expectations because production had to adapt to the software, whereas with MES, it should be exactly the other way around.

When software is built for a specific case and then used in a different environment, it creates friction like sand in a chain. Unless this has been taken into account in the core architecture of the software. This is exactly where the ISA95 standard proves its value. This became clear when we implemented the Ikologik MES platform for Allgro.

Short batches with high frequency

With a high number of batches per day and many associated variables, clear operator instructions, quick machine changeovers and minimizing errors are the key elements. It is essential to deliver all work orders and quality tasks digitally to the operator, enabling fast responses in a dynamic production environment. Paperless, error-free, no-hassle and easy for last-minute changes. The vertical packer, metal detector, labeler and checkweigher on each line, they all receive their settings automatically, triggered by another action in the chain.

Bridge the gap

The ERP system delivers work orders, recipes and customer information. MES completes this information with a fine-scheduler to optimise on-the-floor-planning and instructions to the operator. These instructions hold information on what to do, how and when but are also accompanied with the tasks needed to insure quality. Quality has become an integrated element, part of the work, not the extra task and no question about it.

But production also feeds the ERP with the results. That means that with minimal effort, a two-way communication is setup. No prints, no administration,... the gap between office and production is bridged.

About Allgro

Allgro has specialised in both cutting and wholesaling vegetables and fruit since 1990. Most products are sourced locally from Belgian growers and auctions, ensuring top quality at a fair price. Operating from their production plant in Sint‑Lievens‑Houtem between Ghent and Aalst, over 25 tons of products passes daily for more than 600 customers across Belgium, France and Luxembourg. These include meal production facilities, catering companies and large kitchens.

Continuous investment in modern machinery is essential to keep evolving. But counting over 100 employees and the second generation now at the helm, investing in people is just as important. A lot of effort is put into preserving a warm, family atmosphere where down-to-earth attitude and genuine connection matter. An extension of this mindset that highlights care for one another, is the strong focus on sustainability. Every contribution is seen as an opportunity to do better. This includes the use of solar energy, minimal waste and eco-friendly packaging today but new ambitious projects gradually take form.